Learn the Hierarchy of Fall Protection Today Anchor Safe

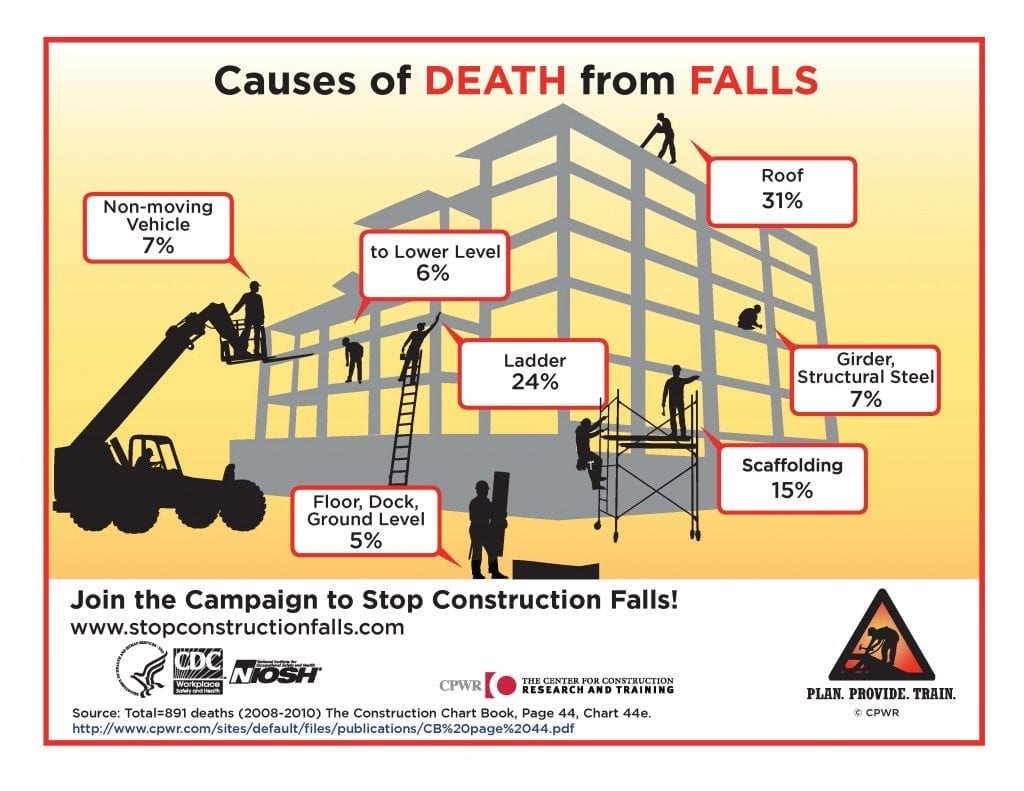

A fall protection plan is a general term for the policy and procedures used to identify fall hazards, and the measures taken to prevent injury. Included in this plan is selecting, assembling, maintaining, inspecting, using, and dismantling equipment such as ladders, scaffolds, or platforms used for working at heights as well as any fall.

Fall Protection Plan Template

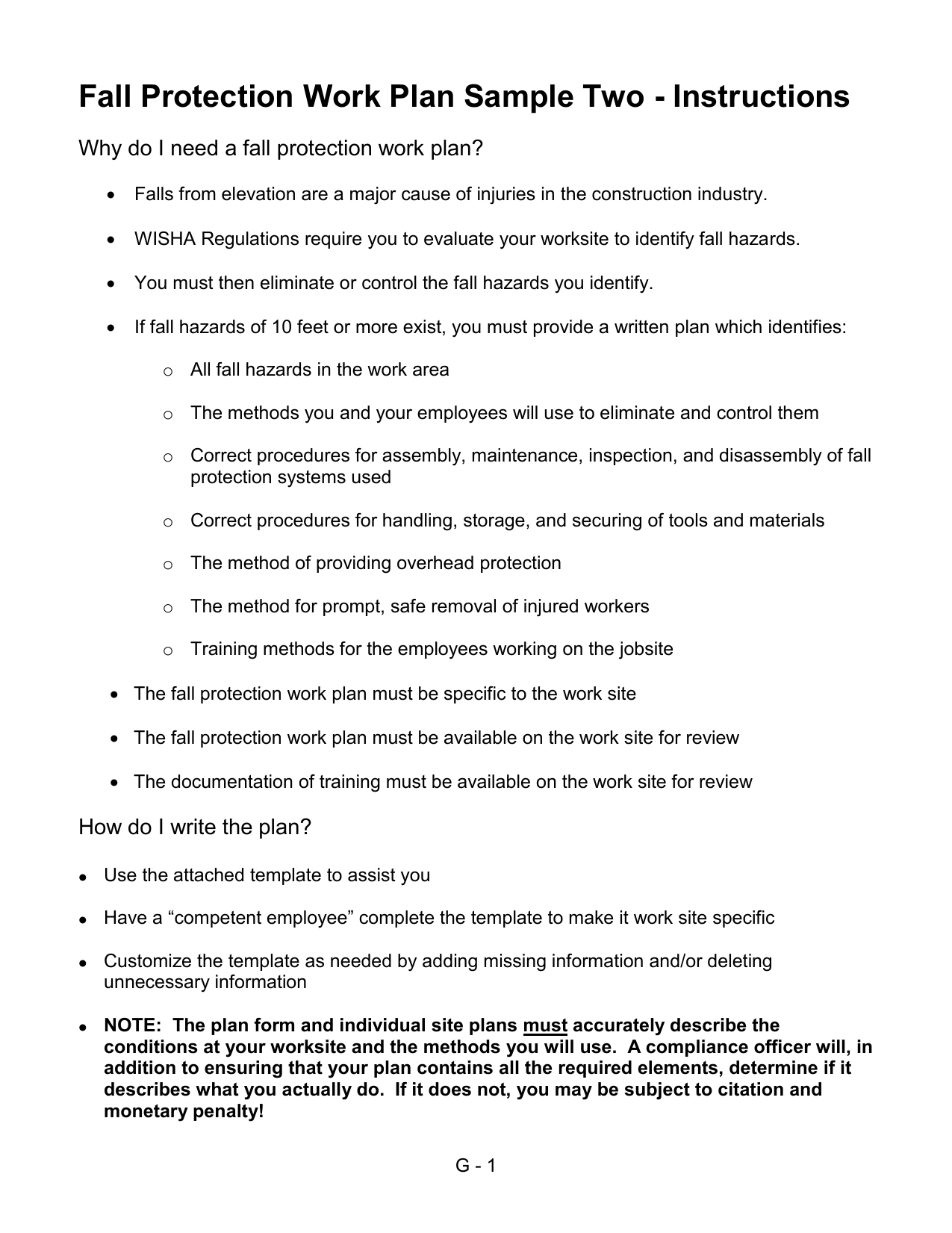

A fall protection plan is composed of eight sections: 1. Jobsite info. Include information about the job, such as the address and name of the project, as well as contact information for the general contractor, superintendent, and foreman. Include contact info for those trained in first aid and fall rescues. 2.

Infographics & Tip Sheets Stop Construction Falls

As much as possible, OSHA has aligned fall protection requirements for general industry with those for construction, easing compliance for employers who perform both types of activities. For example, OSHA's final rule on this replaces the outdated general industry scaffold standards with a requirement that employers comply with OSHA's.

8 Step Fall Protection Plan for OSHA Requirements Rigid Lifelines

This Fall Protection Program for General Industry has been developed in accordance with the requirements of Title 29, Sections 1910.140 and 1910.21-30 of the Code of Federal. o Ensure a rescue plan is in place in the event an employee falls; and o Participate in the incident investigation, if one occurs.

Free Fall Protection Plan Template

General Industry Fall Hazards . The following are identified general industry fall hazards:. the supervisor shall develop and implement a fall protection plan which meets the requirements of OSHA 1926.502 (k). Each employee on a walking/working surface 6 feet or more above a lower level where leading edges are under

Fall Protection for General Industry DVD Training

This is a fall protection plan example structure with recommended sections: Site-specific Fall Hazards and Details. Fall Protection Systems to be Used. Procedures for Assembly, Maintenance, Inspection, Disassembly of Fall Protection System to be Used. Procedures for Handling, Storage, Securing Tools and Materials.

Fall Safety Resources for Planning, Prevention & Protection

Fall protection plan requirements detail the necessary elements for an effective fall protection plan, including hazard identification, selection of prevention and protection systems, and the establishment of rescue procedures. The tailored nature of these requirements is vital because they address the unique risks and challenges of each.

Fall Protection for General Industry Online Training Course

This post is a continuation of Part 1, 7 Keys to Understanding the Fall Protection Regulation changes. The General Requirements in 1910.22; Ladders 1910.23; Scaffolding 1910.27(a) Duty to have Fall Protection and Falling Object Protection; In this section, the duty for fall protection has brand new wording that is used in 29 CFR 1926 Subpart M.

Employers Duty To Have Fall Protection Is When JonathonLilee

A fall protection plan must Be used for . construction work. only. A fall protection plan may be applied to . general industry work, but only on a case-by-case basis as determined by the local compliance officer (DOE site manager or designee). Demonstrate why conventional fall protection cannot or should not be used

The ABC’s and 123’s of Fall Protection Infographics Directory

Publication No. HS15-001B (03-22) The following Fall Protection for the Construction Industry Sample Written Program is provided as a guide to assist employers and employees in complying with the requirements of the Occupational Safety and Health Administration (OSHA) standard 29 CFR 1926, Subpart M. It is not intended to supersede the.

Fall Safety Resources for Planning, Prevention and Protection

An overhead fall protection system, such as a ceiling mounted horizontal lifeline system, can offer the right protection to keep these workers safe. To provide access to multiple workers at once, XSPlatforms developed a revolutionary lifeline system which as the word "innovation" written all over it. Read more about this system and its.

8 Step Fall Protection Plan for OSHA Requirements Rigid Lifelines

PPE. Fall Protection. Fall Prevention Training for General Industry Employees. Feb. 3, 2017. OSHA's efforts to revise and update the existing walking-working surfaces standard for general industry have been ongoing since 1973. A focus of the update is employee training. Here's what you need to know.

what are the 4 methods of fall protection lilliefaruolo

When the employer can demonstrate that it is not feasible or creates a greater hazard to use guardrail, safety net, or personal fall protection systems on residential roofs, the employer must develop and implement a fall protection plan that meets the requirements of 29 CFR 1926.502(k) and training that meets the requirements of 29 CFR 1926.503(a) and (c).

Working at Heights Do You Have a Fall Protection Plan? Is It Current? Is Proper Training in

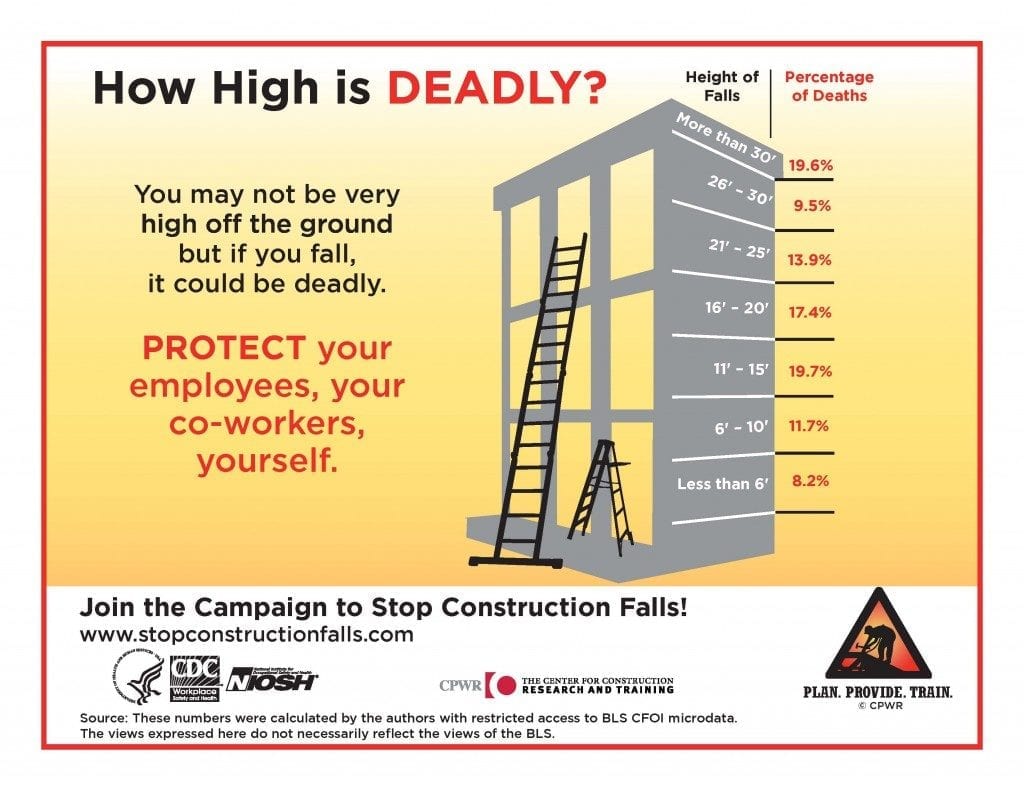

Fall Hazards - Definition •Anytime you are working at a height of 4 feet or more, you are at risk •OSHA generally requires that fall protection be provided at • 4 feet in general industry and • 6 feet in construction industry. •Fall protection must be provided when working over dangerous equipment and machinery, regardless of the fall

General Industry Fall Protection Tips iSi Environmental

Element 1: Assessing the Hazards for the Fall Protection Plan. Hazard identification is the first step in demonstrating due diligence and is always the first step in any safety plan. For general industry, OSHA requires fall protection beginning at a height of four feet. In construction, fall protection is required above six feet.

Fall Protection Systems For Construction and General Industry YouTube

These Sample Written Programs are designed to help you create customized programs for your specific needs. Most samples are in Word format so you can easily adapt them. You might also like to visit Safety Writer, which is hosted by the consultation program at the University of South Florida. Originally designed for OSHA employees, it is now.

.